UNS N07718 AMS 5662 Forgings Nickel Alloys

UNS N07718 AMS 5662 Forgings Nickel Alloys Manufacturer

AMS 5662 is a designation of Nickel Inconel 718, itself a nickel-chromium alloy with high strength, corrosion and oxidation resistance, and excellent tensile and impact strength at cryogenic temperatures.

Full chemical composition is 52.5Ni – 19Cr – 3.0Mo – 5.1Cb (Nb) – 0.90Ti – 0.50Al – 18Fe

Table of Contents

ToggleThis designation is made by solution annealing at 1775°F (968°C) followed by rapid cooling, usually in water, and precipitation hardening at 1325°F (718°C) for 8 hours and furnace cool to 1150°F (620°C).

It is available in bars, forgings, rings or custom tube and thus it is a perfect option for parts that require resistance to creep and stress-rupture of up to 1300°F (705°C), and oxidation resistance of up to 1800°F (982°C).

AMS 5662 is an excellent choice for parts where there is a concern of rupture life, notch rupture life, and rupture ductility.

Efficiency when welding is about 100% with the gas tungsten-arc process and using the proprietary Nickel Filler Metal 718. Nickel Inconel 718 AMS 5662 can be age-hardened directly, without stress relief. Pankh Steel is the high quality UNS N07718 AMS 5662 Forgings Nickel Alloys Manufacturer in India

Products

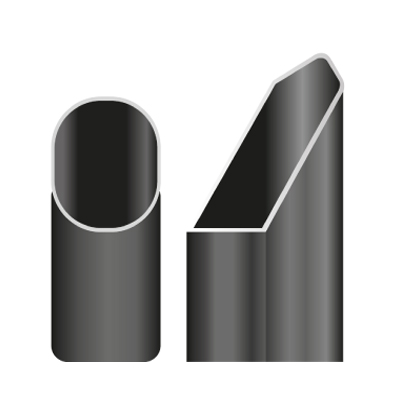

AMS 5662 Custom Tube

- Alloy: Nickel

- Type: Inconel 718

- UNS: N07718

AMS 5662 Inconel 718 Bar

- Alloy: Nickel

- Type: Inconel 718

- UNS: N07718

AMS 5662 Inconel 718 Forging

- Alloy: Nickel

- Type: Inconel 718

- UNS: N07718

AMS 5662 Inconel 718 Ring

- Alloy: Nickel

- Type: Inconel 718

- UNS: N07718

The Alloy Nickel Inconel 718 is a nickel-chromium alloy with high strength and corrosion resistance. It is used at temperatures ranging from -423° to 1300°F (-253° to 705°C). As an age-hardenable alloy, the alloy Nickel Inconel 718 can be readily fabricated in very complex parts, and its welding characteristics are also outstanding. It also has good tensile, fatigue, creep, and rupture strength, which combined with easy fabrication and corrosion resistance.

Due to its combination of properties, the Nickel Inconel 718 is used for a wide range of applications, such as liquid-fueled rockets, rings, and casings, various formed sheet metal parts for aircraft and land-based gas turbine engines, cryogenic tankage, and for fasteners and instrumentation parts. We are the leading Manufacturer of UNS N07718 AMS 5662 Forgings Nickel Alloys.

Tech Steel & Materials offers the alloy Nickel Inconel 718 in 9 sub-type specifications, each in multiple and customized shapes/forms:

- AMS 5589 (Tubing)

- AMS 5590 (Tubing)

- AMS 5596 (Foil, Plate, Sheet or Strip)

- AMS 5597 (Plate, Sheet or Strip)

- AMS 5662 (Bar, Forging, Ring or Custom Tube)

- AMS 5663 (Bar, Forging, Ring or Custom Tube)

- AMS 5664 (Bar, Forging, Ring or Custom Tube)

- AMS 5832 (Wire)

- AMS 5962 (Bar and Wire)

We offer a fully customized line of tube drawing and seamless tubing for Nickel 718. Learn more about our Custom Tubing Services.

The Composition of Nickel Inconel 718

The composition of the particular alloy is the following:

| Element | Limiting Chemical Composition (%) |

| Nickel (plus Cobalt) | 50%-55% |

| Chromium | 17%-21% |

| Niobium (plus Tantalum) | 4.75%-5.50% |

| Molybdenum | 2.80%-3.30% |

| Titanium | 0.65%-1.15% |

| Aluminum | 0.20%-0.80% |

| Cobalt | 1% max |

+Carbon | 0.08% max |

| Manganese | 0.35% max |

| Silicon | 0.35% max |

| Phosphorus | 0.015% max |

| Sulfur | 0.015% max |

| Boron | 0.006% max |

| Copper | 0.30% max |

| Iron | Balance* |

*Not exclusively to the element mentioned, but that one predominates other elements that are used only in minimal quantities.

Fabrication and Working Instructions

It is highly recommended to follow the next instructions when Nickel Inconel 718 is heated, in order to minimize oxide layers forming.

- Fuels used for the heating must be extremely low in sulfur;

- Both the furnace and material should be heated at the correct temperatures;

- Before putting it into the furnace, completelyclean the alloy from oil, paint, grease, and shop soil;

- For forging or open annealing, the furnace atmosphere should be slightly reducing, with at least 2% carbon monoxide;

- Keep the pressure in the furnace slightly positive so that there is no air infiltration;

Please note that in reducing atmospheres, a green-black film of oxide forms (easy to remove). In oxidizing atmospheres, on the other hand, a black scale forms that is very difficult to remove.

Nickel Inconel 718 joint efficiency when welding is about 100% for parts that have been annealed, welded and aged. Due to the slow response, it can be age-hardened directly, without any sort of stress relief. Welding should be done with the gas tungsten-arc process, using the proprietary Nickel Filler Metal 718.

If the Alloy Nickel Inconel 718 is cold-worked or precipitation hardened, use of silver brazing compounds is not recommended, as they can cause stress and crackling to the alloy. Brazing compounds with cadmium should also be avoided because that element can aggravate the cracking that started from silver or other elements

Physical Constants

| Density | Annealed: 0.296 lb/in3 |

| Annealed and aged: 0.297 lb/in3 | |

| Melting Range | 2300° to 2437°F (1260° to 1336°C) |

| Specific Heat at 21°C (70°F) | 0.104 Btu/lb-°F |

| Permeability at 200 oersted and 21°C (70°F) | Annealed material: 1.0013 |

| Annealed and aged material: 1.0011 | |

| Curie Temperature °C (°F) | Annealed material: <-320°F (<-196°C) |

| annealed and aged material: -170°F (-112°C) |

Heat Treating and Mechanical Properties of Nickel Inconel 718

The Alloy Nickel Inconel 718 is specified as solution annealed and precipitation hardened by the precipitation of the secondary phases into the metal matrix. The precipitation takes place at 1100° to 1500°F (593° to 815°C). In order for the metallurgical reaction to properly take place, the aging constituents, such as aluminum, titanium, and niobium, must be dissolved in the matrix. Otherwise, the alloy may not reach full strength. For that to happen, solution annealing is utilized.

Overall, three heat treatments are utilized for the Nickel Inconel 718:

- Solution anneal at 1700 to 1850°F (925° to 1010°C) followed by rapid cooling, usually in water. Then, precipitation hardening is done at 1325°F (718°C) for 8 hours and furnace cool to 1150°F (620°C). Hold at 1150°F (620°C) for a total aging time of 18 hours, followed by air cooling.

This treatment is optimal when there is a concern of rupture life, notch rupture life, and rupture ductility. It is also associated with high fatigue strength and room-temperature tensile and yield strengths.

- Solution anneal at 1900° to 1950°F (1037° to 1065°C) followed by rapid cooling, usually in water. Then, precipitation hardening is done at 1400°F (760°C) for 10 hours and furnace cool to 1200°F (650°C). Hold at 1200°F for a total aging time of 20 hours, followed by air cooling.

This treatment is preferred for tensile-limited applications. It produces the best transverse ductility in heavy sections, better impact strength, and low-temperature notch strength. Compared to the other treatment though, it has a tendency to produce notch brittleness in stress rupture.

- Solution anneal at 1850° to 1900°F (1010° to 1037°C), followed by aging at 1450°F (790°C) for six to eight hours and then air cooled. Produced under the NACE specification MR0175, this treatment is used for oil field applications.

Why Choose Us :

- You can get the perfect material according to your requirement at the least possible price.

- We also offer door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

- The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

- guarantee to give a response within 24hours(usually in the same hour)

- You can get stock alternatives, mill deliveries with minimizing manufacturing time.

- We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

People Also Searched for

| Stainless Steel ASTM A TP 304 Flanges Manufacturer, Stainless Steel ASTM A TP 304L Flanges Manufacturer, Stainless Steel ASTM A TP 304H Flanges Manufacturer, Duplex Steel ASTM 815 Flanges Manufacturer, Duplex Steel UNS S31803 Flanges Manufacturer, Duplex Steel S32750 Flanges Manufacturer, Duplex Steel S32760 Flanges Manufacturer, Duplex Steel S32205 Flanges Manufacturer, Nickel UNS N02200 Flanges Manufacturer, Nickel UNS N02201 Flanges Manufacturer, Alloy 20 Flanges Manufacturer, ASTM A 403 WP TP 304 Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 304L Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 304H Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 316 Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 316L Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 316H Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 316Ti Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 309 Butt Weld Fittings Manufacturer, ASTM A 403 WP TP 904L Butt Weld Fittings Manufacturer, ASTM A 815- UNS S31803 Butt Weld Fittings Manufacturer, ASTM A 815- UNS S32750 Butt Weld Fittings Manufacturer, ASTM A 815- UNS S32760 Butt Weld Fittings Manufacturer, ASTM A 815- UNS S32205 Butt Weld Fittings Manufacturer, ASTM A 234 WPB – WP5 Butt Weld Fittings Manufacturer, ASTM A 234 WPB – WP9 Butt Weld Fittings Manufacturer, ASTM A 234 WPB – WP12 Butt Weld Fittings Manufacturer, ASTM A 234 WPB – WP22 Butt Weld Fittings Manufacturer, ASTM A 234 WPB – WP91 Butt Weld Fittings Manufacturer, ASTM A234 WPB Butt Weld Fittings Manufacturer, A420 WPL3 Butt Weld Fittings Manufacturer, A420 WPL6 Butt Weld Fittings Manufacturer, MSS-SP-75 WPHY 42 Butt Weld Fittings Manufacturer, MSS-SP-75 WPHY 46 Butt Weld Fittings Manufacturer, MSS-SP-75 WPHY 52 Butt Weld Fittings Manufacturer, C71640 Butt Weld Fittings Manufacturer, UNS N02200 Butt Weld Fittings Manufacturer, UNS N02201 Butt Weld Fittings Manufacturer, UNS N04400 Butt Weld Fittings Manufacturer, UNS N05500 Butt Weld Fittings Manufacturer, Alloy 20 Butt Weld Fittings Manufacturer, UNS N06600 Butt Weld Fittings Manufacturer, UNS N06601 Butt Weld Fittings Manufacturer, UNS N06625 Butt Weld Fittings Manufacturer, UNS N08800 Butt Weld Fittings Manufacturer, UNS N08810 Butt Weld Fittings Manufacturer, UNS N10276 Butt Weld Fittings Manufacturer, UNS N06022 Butt Weld Fittings Manufacturer, ASTM A 249 Stainless Steel Welded Manufacturer, ASTM A 268 Stainless Steel Welded Manufacturer, ASTM A 270 Stainless Steel Welded Manufacturer, ASTM A 554 Stainless Steel Welded Manufacturer, ASTM A 1016 Stainless Steel Welded Manufacturer. |

| We Supply ASTM A234 WPB Butt weld Fittings in Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal, Mumbai, Navi Mumbai, Pune, Nashik, Nagpur, Solapur, Kolhapur, Ambernath, Ahmednagar, Latur, Ahmadabad, Surat, Rajkot, Vadodara, Panaji, Madgaon, Chennai, Kolkata, Hyderabad, Bengaluru, Delhi, New Delhi, Ludhiana, Chandigarh, Raipur, Bhopal, Jamshedpur, Vishakhapatnam, Cochin, Ghaziabad, Noida, Gurugram, Bhillai, Durgapur, Vijaywada, Kanpur etc. |