UNS Flanges

UNS Flanges Manufacturer

UNS N04400, N05500, Alloy 20 & High-Performance Alloy Flanges Manufacturer – Pankh Stainless

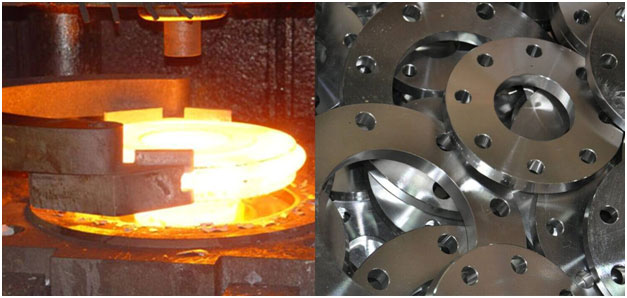

At Pankh Stainless, we are a globally trusted manufacturer, supplier, and exporter of premium-grade UNS N04400 Flanges, UNS N05500 Flanges, Alloy 20 Flanges, UNS N06600 Flanges, UNS N06601 Flanges, UNS N06625 Flanges, UNS N08800 Flanges, UNS N08810 Flanges, UNS N10276 Flanges, UNS N06022 Flanges, UNS N10665 Flanges, and UNS N06455 Flanges.

We specialize in providing corrosion-resistant, heat-resistant, and high-strength alloy flanges for critical industries such as oil & gas, petrochemicals, power generation, seawater systems, marine engineering, chemical processing, and high-temperature service environments.

Table of Contents

ToggleWe proudly serve customers across South Africa, Saudi Arabia, and UAE, including major industrial cities such as Cape Town, Jeddah, Riyadh, Dubai, and many more.

Leading High-Performance Alloy Flanges Manufacturer

Pankh Stainless is known for world-class quality, strict metallurgical precision, and advanced manufacturing standards. Our product range includes:

- UNS N04400 (Monel 400) Flanges

- UNS N05500 (Monel K500) Flanges

- Alloy 20 (UNS N08020) Flanges

- UNS N06600 (Inconel 600) Flanges

- UNS N06601 (Inconel 601) Flanges

- UNS N06625 (Inconel 625) Flanges

- UNS N08800 (Incoloy 800) Flanges

- UNS N08810 (Incoloy 800H) Flanges

- UNS N10276 (Hastelloy C276) Flanges

- UNS N06022 (Hastelloy C22) Flanges

- UNS N10665 (Hastelloy B2) Flanges

- UNS N06455 (Hastelloy B3) Flanges

Each flange is manufactured with accurate dimensions, smooth surface finish, leak-proof joints, and compliance with ASTM, ASME, API, DIN, EN, JIS, and other global standards.

UNS N04400 Flanges Manufacturer

Monel 400 flanges offer exceptional corrosion resistance in seawater, acidic solutions, and alkaline environments.

Applications: Marine systems, desalination plants, offshore structures, valves, pumps, and heat exchangers.

UNS N05500 Flanges Manufacturer

Monel K500 provides higher strength and hardness compared to N04400, with outstanding resistance to sour gas and saltwater.

Applications: Oil & gas equipment, pump shafts, marine hardware, turbine components.

Alloy 20 Flanges Manufacturer

Known for superior resistance against sulfuric acid, Alloy 20 is widely used in chemical and petrochemical industries.

Applications: Chemical tanks, acid-processing equipment, pharmaceuticals.

UNS N06600 (Inconel 600) Flanges Manufacturer

A high-temperature alloy suitable for temperatures up to 1,100°C.

Applications: Furnaces, heat-treating systems, nuclear plants.

UNS N06601 (Inconel 601) Flanges Manufacturer

A versatile oxidation-resistant alloy for intense heat environments.

Applications: Petrochemical processing, thermal equipment.

UNS N06625 (Inconel 625) Flanges Manufacturer

Offers excellent fatigue strength, creep resistance, and corrosion resistance.

Applications: Aerospace, offshore platforms, chemical plants.

UNS N08800 (Incoloy 800) Flanges Manufacturer

A high-strength, oxidation-resistant alloy used in high-heat applications.

Applications: Steam systems, boilers, petrochemical heaters.

UNS N08810 (Incoloy 800H) Flanges Manufacturer

Enhanced creep-strength alloy suitable for long-term elevated temperature service.

UNS N10276 (Hastelloy C276) Flanges Manufacturer

The most corrosion-resistant alloy, suitable for aggressive chemicals.

Applications: Acid plants, pharmaceutical reactors.

UNS N06022 (Hastelloy C22) Flanges Manufacturer

Preferred for environments involving sulfuric acid, chlorine, and seawater exposure.

UNS N10665 (Hastelloy B2) Flanges Manufacturer

Superior resistance to hydrochloric acid and reducing chemical environments.

UNS N06455 (Hastelloy B3) Flanges Manufacturer

Designed for extreme chemical-processing environments with enhanced thermal stability.

Flange Types Manufactured by Pankh Stainless

We supply all industrial flange types including:

- Weld Neck Flanges

- Slip-On Flanges

- Blind Flanges

- Socket Weld Flanges

- Lap Joint Flanges

- Threaded Flanges

- Orifice Flanges

- Long Weld Neck Flanges

- Reducing Flanges

- RTJ Flanges

- Plate Flanges

Every flange is tested through PMI testing, hydro testing, ultrasonic testing, and mechanical inspection to ensure reliability and safety.

Pankh Stainless – Trusted Supplier in South Africa

We are a recognized UNS N04400, N05500, Alloy 20, Inconel, Incoloy, and Hastelloy Flanges Manufacturer in South Africa, supplying across major industrial locations such as:

- Genadendal

- Swellendam

- Langebaan

- Knysna

- Lethabong

- Cape Town

- Jeffreys Bay

- Amanzimtoti

Our flanges are extensively used in South Africa’s oil & gas, mining, marine engineering, and water treatment industries.

Pankh Stainless – Supplier in Saudi Arabia

We supply a wide range of UNS-grade flanges across Saudi Arabia, including:

- Al Jubail

- Jeddah

- Riyadh

- Al Khobar

- Dhahran

- Ad Diriyah

Pankh Stainless supports the booming Saudi petrochemical, refinery, and desalination sectors with durable, high-performance alloy flanges.

Pankh Stainless – Leading Supplier in UAE

We also deliver UNS N04400 to UNS N10665 Flanges across the United Arab Emirates:

- Abu Dhabi

- Dubai

- Al Jazirah Al Hamra

- Ruwais

- Umm Al Quwain

Our products are trusted by EPC contractors, oil companies, construction firms, and industrial manufacturers across UAE.

Why Choose Pankh Stainless?

Premium Raw Materials

We source high-purity alloys from certified mills.

Advanced Manufacturing Technology

CNC machining, heat treatment, precision forging, and automated testing ensure unmatched accuracy.

Global Quality Compliance

Every product complies with ASTM, ASME, ANSI, API, and EN standards.

Large Inventory & Fast Delivery

We maintain ready stock of Monel, Inconel, Incoloy, Alloy 20, and Hastelloy flanges for quick dispatch across South Africa, Saudi Arabia, and UAE.

Customized Flanges

We manufacture flanges in custom sizes, pressure ratings (150#, 300#, 600#, 900#, 1500#), and bespoke designs as per client needs.

Industry-Specific Solutions

Our flanges serve industries including:

Oil & Gas • Petrochemicals • Chemicals • Power Plants • Desalination • Fertilizer • Sugar Industry • Marine • Heat Exchangers • Water Treatment Plants

Industries We Serve

- Oil & Gas Refineries – corrosion-resistant flanges for aggressive chemicals

- Petrochemical Plants – high-temperature alloy flanges

- Marine & Offshore – seawater-resistant Monel flanges

- Mining Industry – durable high-strength alloy components

- Chemical Processing Units – Alloy 20 & Hastelloy grades

- Water Desalination Plants – Monel & Inconel grades

- Power Generation – long-life high-temperature flanges

Service Locations Covered

South Africa:

Genadendal, Swellendam, Langebaan, Knysna, Lethabong, Cape Town, Jeffreys Bay, Amanzimtoti

Saudi Arabia:

Al Jubail, Jeddah, Riyadh, Al Khobar, Dhahran, Ad Diriyah

UAE:

Abu Dhabi, Dubai, Al Jazirah Al Hamra, Ruwais, Umm Al Quwain

Order High-Performance UNS Alloy Flanges from Pankh Stainless

Whether you need UNS N04400 Flanges, UNS N05500 Flanges, Alloy 20 Flanges, or Hastelloy & Inconel Series Flanges, Pankh Stainless provides reliable, precision-engineered solutions for your project.

We ensure:

- Reliable performance

- Long service life

- Competitive pricing

- On-time delivery

- 100% material traceability

- Complete documentation (MTC, EN 10204 3.1, test reports)

Contact Pankh Stainless Today

For inquiries, orders, or quotations for UNS N04400 Flanges, UNS N05500 Flanges, Alloy 20 Flanges, UNS N06600 / N06601 / N06625 / N08800 / N08810 / N10276 / N06022 / N10665 / N06455 Flanges, connect with us.

Pankh Stainless – Your Trusted High-Performance Alloy Flange Manufacturer & Global Supplier